It’s been a busy few months! We finally completed this massive order of mini beam trusses for Kish Rigging! (Mini means 8 ft) This order was for 50 total and we have been working on it since December! So much work goes into this process. All hands were on deck for this project! These are made with 6061 aluminum and welded together with 5356 filler rod for high strength. Our trusses are known for their durability!

It’s been a busy few months! We finally completed this massive order of mini beam trusses for Kish Rigging! (Mini means 8 ft) This order was for 50 total and we have been working on it since December! So much work goes into this process. All hands were on deck for this project! These are made with 6061 aluminum and welded together with 5356 filler rod for high strength. Our trusses are known for their durability!

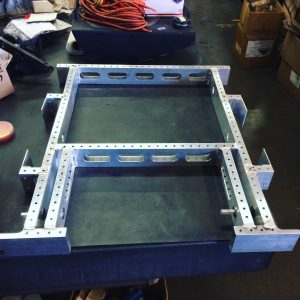

We had this large steel box come into the shop! This box is for an anodizing tank. The walls were massively corroded from the chemical processes of anodizing. It broke apart and came to us in four pieces! It had to be welded on both the inside and the outside. When it was time for the inner welds. our employee, Javier, had to climb inside with a ladder. He spent a good four hours in that box that day. It was worth the hard work because the customer was very pleased to get it back and get back to work at his own business!

We had an aluminum fixture in house again for welding. This one in particular is an electronic s vibration test fixture for vacuum chamber qualifications. In order for the weld to penetrate, we had to pre-heat the fixture. Then it was welded to customer specifications. it was done using the TIG process and 4943 filler.