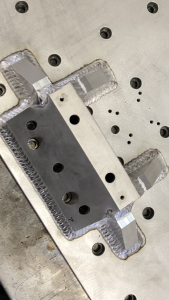

Here we have some medium size structures. These frames are about 2 1/2 ft tall by 2 ft wide and 1 1/2 inches thick. We laid down some huge weaves to hold these beasts together. Made from 6061 aluminum, as usual!

Here we have some medium size structures. These frames are about 2 1/2 ft tall by 2 ft wide and 1 1/2 inches thick. We laid down some huge weaves to hold these beasts together. Made from 6061 aluminum, as usual!

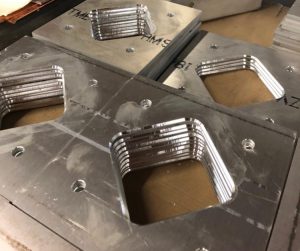

This is approximately 240 lbs. of solid ,magnesium, which just so happens to be one of the exotic metals that we can work with. With magnesium being even lighter than aluminum, at 240 lbs. you know this weldment had to be huge! It consisted of two 3″ x 3.5″ bars attached to a 1.5″ thick plate, all 40″ long. The welds wrapped all the way around the bars. in all it was about 175 inches of weave welds! Not bad, huh?

This is approximately 240 lbs. of solid ,magnesium, which just so happens to be one of the exotic metals that we can work with. With magnesium being even lighter than aluminum, at 240 lbs. you know this weldment had to be huge! It consisted of two 3″ x 3.5″ bars attached to a 1.5″ thick plate, all 40″ long. The welds wrapped all the way around the bars. in all it was about 175 inches of weave welds! Not bad, huh?

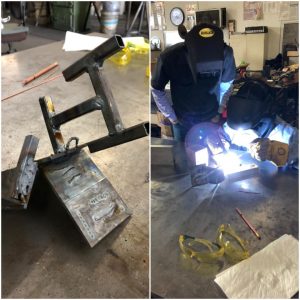

A few weeks ago, we held one of our student workshops. In attendance we had kids from CSUN and UCLA, as well as teachers from Chaminade and even family members and just members of the community that were interested in expanding their skills. We always have a great time teaching, and watching how fast some of our students learn. Just a couple weeks later, we even had one of the people in attendance come back to the shop and weld his own part by himself! On the right you see two students practicing , and on the left is one of their “sculptures” of the pieces they practiced on!

A few weeks ago, we held one of our student workshops. In attendance we had kids from CSUN and UCLA, as well as teachers from Chaminade and even family members and just members of the community that were interested in expanding their skills. We always have a great time teaching, and watching how fast some of our students learn. Just a couple weeks later, we even had one of the people in attendance come back to the shop and weld his own part by himself! On the right you see two students practicing , and on the left is one of their “sculptures” of the pieces they practiced on!

Here we have some pictures of the frame for UCLA’s entry to the Baja SAE competition! This buggy frame was designed by engineering students at UCLA and all connections were laser cut and bent to dimension by computer. All the pieces fit like a glove, much to the delight of the team, and our workers who welded it! Javier worked with the students, assembling and tacking it together, and Terry did a good amount of the final welds. This chassis is made out of 4130 thin wall tube, and welded with ER80-S2 filler rod, which is a good strength match. Because the tubing is so thin, post weld stress relief or hardening in not needed or specified by the UCLA team. We are excited to have our logo on their buggy, and we wish them the best of luck in the upcoming race!

Here we have some pictures of the frame for UCLA’s entry to the Baja SAE competition! This buggy frame was designed by engineering students at UCLA and all connections were laser cut and bent to dimension by computer. All the pieces fit like a glove, much to the delight of the team, and our workers who welded it! Javier worked with the students, assembling and tacking it together, and Terry did a good amount of the final welds. This chassis is made out of 4130 thin wall tube, and welded with ER80-S2 filler rod, which is a good strength match. Because the tubing is so thin, post weld stress relief or hardening in not needed or specified by the UCLA team. We are excited to have our logo on their buggy, and we wish them the best of luck in the upcoming race!