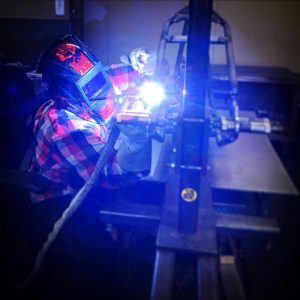

We got a surprise in the mail-a wonderful ‘thank you’ card from UCLA’s Steel Bridge Team, and some great photos of their bridge during competition last month. Jaytech’s Terry and Haley helped the team assemble and then tacked and welded the structure for competition. Since then, we have had the team here for two welding workshops to gear up for next year. Go Bruins!

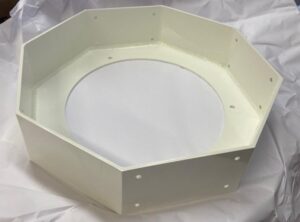

We’re still here, busy as ever at Jaytech! As you can see we’ve got our benches full of lots of different projects. We’re happy to have several production jobs in house (of course walk-ins and repairs are still welcome). It’s also great that most of this work is our all-time favorite metal-ALUMINUM!

We’re still here, busy as ever at Jaytech! As you can see we’ve got our benches full of lots of different projects. We’re happy to have several production jobs in house (of course walk-ins and repairs are still welcome). It’s also great that most of this work is our all-time favorite metal-ALUMINUM!

These past few months have been so busy that we’ve had no time to post on the web! Instead we’ve been hard at work building structures out of aluminum (Terry’s favorite) for a telecommunications company that we are so happy to have as a loyal customer as well as stainless steel and titanium repairs and weldments (Haley’s favorite). Of course we have had much more than that too but these are just a few pictures for a peak at what we’ve been up to!

These past few months have been so busy that we’ve had no time to post on the web! Instead we’ve been hard at work building structures out of aluminum (Terry’s favorite) for a telecommunications company that we are so happy to have as a loyal customer as well as stainless steel and titanium repairs and weldments (Haley’s favorite). Of course we have had much more than that too but these are just a few pictures for a peak at what we’ve been up to!

Here we have a muffler that our customer needed modified. What’s special about it though is that it’s made out of titanium! You can see in this picture how Terry has this taped up and hooked up to the purge bottle which is expelling all the oxygen inside and filling it with argon. This is a necessary step for welding any kind of titanium tubing!

True story! If Haley had been born a boy, well, you know the rest! That makes it even more fitting that she did almost all the welding on this Harley Davidson motorcycle frame. Our customer’s client wanted this old bike she’s had for decades modified. Haley had fun doing what she does best (hint: it’s steel and stainless) and made this bike frame something beautiful that it’s rider will be proud to keep riding for decades to come!

This exhaust system had leaks coming from where these two band clamps were holding the pieces together. Our customer wanted the whole thing welded solid so the clamps could be removed. Of course with this being a stainless steel exhaust, we needed to purge it with argon to keep the inside of the pipes from getting corrosion on the back side of the weld. We love doing work like this, if you have any exhaust systems in need of repair, bring it on in!

This exhaust system had leaks coming from where these two band clamps were holding the pieces together. Our customer wanted the whole thing welded solid so the clamps could be removed. Of course with this being a stainless steel exhaust, we needed to purge it with argon to keep the inside of the pipes from getting corrosion on the back side of the weld. We love doing work like this, if you have any exhaust systems in need of repair, bring it on in!

This post is a bit late, but one of the things Haley did to keep herself busy this past Christmas was making Christmas tree ornaments! She got the help of Peggy, who programmed the cut patterns on the computer, and Terry, who used the plasmacam to cut out the shapes. Haley used stainless steel filler rod to decorate the ornaments with patterns, stripes, trees, snowflakes, and even Santa!

Here is just a couple of examples of some of the exotic metals we frequently work with. The first is the repair of a crack on a titanium exhaust. These always need to be purged with argon to ensure there is no corruption on the inside! The second is a large piece of magnesium that needed holes filled. Titanium can be welded using a direct current, similar to steel/stainless steel alloys, whereas magnesium needs an alternating electrical current, like aluminum. But it is imperative that you use the correct filler rod!

Recently the shop was occupied by a statue of a woman made entirely out of steel washers! She had fallen down and broken her leg off with a bunch of pieces missing. We carefully put her back together using all the pieces our customer could find and also added a few of our own washers to reinforce her leg so she wouldn’t break again! We think she looks pretty good considering she had already been missing her head! (Her other leg had already been missing too)