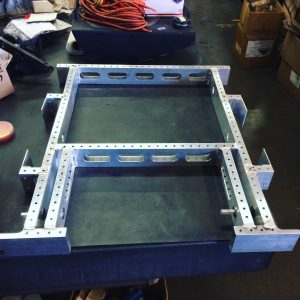

Occasionally we donate our time to local schools! We have worked with CSUN and Chatsworth High School, and just recently we got to work with Reseda High School and weld up this chassis for their robotics team! We love doing what we can to be a contributing part of the community!

Occasionally we donate our time to local schools! We have worked with CSUN and Chatsworth High School, and just recently we got to work with Reseda High School and weld up this chassis for their robotics team! We love doing what we can to be a contributing part of the community!

We had this large steel box come into the shop! This box is for an anodizing tank. The walls were massively corroded from the chemical processes of anodizing. It broke apart and came to us in four pieces! It had to be welded on both the inside and the outside. When it was time for the inner welds. our employee, Javier, had to climb inside with a ladder. He spent a good four hours in that box that day. It was worth the hard work because the customer was very pleased to get it back and get back to work at his own business!

We had an aluminum fixture in house again for welding. This one in particular is an electronic s vibration test fixture for vacuum chamber qualifications. In order for the weld to penetrate, we had to pre-heat the fixture. Then it was welded to customer specifications. it was done using the TIG process and 4943 filler.

Through the months of September. October, and November, Terry holds welding workshops for the steel bridge building team over at California State University at Northridge. He helps them learn how to weld steel well enough so that they can weld their own bridge together at the competition later on that school year. CSUN’s bridge building team is one of the few teams in this nation-wide competition whose students actually weld their own bridge themselves. Quite an achievement! The CSUN team has a history of doing very well in the competition, and over here at Jaytech we are proud to contribute!

Through the months of September. October, and November, Terry holds welding workshops for the steel bridge building team over at California State University at Northridge. He helps them learn how to weld steel well enough so that they can weld their own bridge together at the competition later on that school year. CSUN’s bridge building team is one of the few teams in this nation-wide competition whose students actually weld their own bridge themselves. Quite an achievement! The CSUN team has a history of doing very well in the competition, and over here at Jaytech we are proud to contribute!