These stainless steel sprockets are one of Haley’s favorite things to do! Super tiny steel welds are what she’s best at. We are grateful for our loyal customers who keep bringing in these familiar jobs and keeping us busy during these difficult times.

These stainless steel sprockets are one of Haley’s favorite things to do! Super tiny steel welds are what she’s best at. We are grateful for our loyal customers who keep bringing in these familiar jobs and keeping us busy during these difficult times.

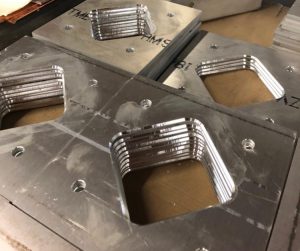

Remember all those trusses we did a while back? We just completed some more work for this customer! The first thing you see here is these bezels. They are meant to go around the rim of a box to prevent damage in case any accidents should occur. The second thing is these plates. We machined all these holes manually. Each component gets a front and a rear plate, which you see here. Both of these jobs were made from aluminum – our specialty!

Remember all those trusses we did a while back? We just completed some more work for this customer! The first thing you see here is these bezels. They are meant to go around the rim of a box to prevent damage in case any accidents should occur. The second thing is these plates. We machined all these holes manually. Each component gets a front and a rear plate, which you see here. Both of these jobs were made from aluminum – our specialty!

We are so glad to stay open during this COVID-19 crisis because of jobs like this! Last week we made 1,000 of these aluminum posts which will hold up glass as a barrier at cash registers in grocery stores. We are so grateful to be able to provide these products to help protect fellow essential workers!

We are so glad to stay open during this COVID-19 crisis because of jobs like this! Last week we made 1,000 of these aluminum posts which will hold up glass as a barrier at cash registers in grocery stores. We are so grateful to be able to provide these products to help protect fellow essential workers!

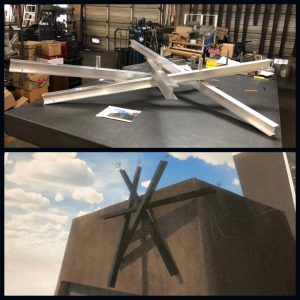

This large sculpture is something we had in the shop recently. It will have lights strung through it and will be hung on the side of a building. We included an picture of another one that is already mounted so you can get an idea of what it will look like. The angles the bars sat at and the way they all laid within each other proved to be an interesting challenge!

This large sculpture is something we had in the shop recently. It will have lights strung through it and will be hung on the side of a building. We included an picture of another one that is already mounted so you can get an idea of what it will look like. The angles the bars sat at and the way they all laid within each other proved to be an interesting challenge!

Being that we are a part of the manufacturing of defense and medical supplies, we are staying open during these uncertain times. However, we are taking extra precautions to keep all of our employees safe! We are practicing social distancing by staying at least 6 feet away from each other, which, luckily, is easy for us with our small number of employees and the size of our shop! Our office manager, Peggy, is also taking some time off of office work to sew masks for all of our workers and their families!

Being that we are a part of the manufacturing of defense and medical supplies, we are staying open during these uncertain times. However, we are taking extra precautions to keep all of our employees safe! We are practicing social distancing by staying at least 6 feet away from each other, which, luckily, is easy for us with our small number of employees and the size of our shop! Our office manager, Peggy, is also taking some time off of office work to sew masks for all of our workers and their families!

This is a picture we forgot to post when we had this thing in the shop! This massive structure took a lot of man power and a lot of hours. It’s a perfect example of not only our welding skills, but also our fabrication skills. We built this whole thing from scratch, starting with bringing in the material lengths and cutting/angling it to size. we had several plates we had to machine as well. This whole thing was built out of over forty pieces and was about seven feet long! This picture shows our top guy, Terry, welding a part of it from underneath while it was lifted by the forklift.

This is a picture we forgot to post when we had this thing in the shop! This massive structure took a lot of man power and a lot of hours. It’s a perfect example of not only our welding skills, but also our fabrication skills. We built this whole thing from scratch, starting with bringing in the material lengths and cutting/angling it to size. we had several plates we had to machine as well. This whole thing was built out of over forty pieces and was about seven feet long! This picture shows our top guy, Terry, welding a part of it from underneath while it was lifted by the forklift.

We had a first time customer in who needed these small fractions welded together. These are mailbox markers! These were especially difficult because of how thin the material was. The thickness of the stainless steel was only 1/8th of an inch. Along with how small these cut outs were, we really had to focus to not melt all the way through and destroy the numbers!

We had a first time customer in who needed these small fractions welded together. These are mailbox markers! These were especially difficult because of how thin the material was. The thickness of the stainless steel was only 1/8th of an inch. Along with how small these cut outs were, we really had to focus to not melt all the way through and destroy the numbers!

We had one of our returning customers in the in the shop again recently. These spindle flange assemblies involve an operation on the turntable, which we love! Having these parts being rotated while we weld allows us to lay down a beautiful weld without stopping and starting! Another thing we get to use on these parts is ER312 filler rod, which is our favorite stainless steel rod. We call it Super Missile Rod because it can be used to weld unknown or dissimilar alloys of steel or stainless steel!

We had one of our returning customers in the in the shop again recently. These spindle flange assemblies involve an operation on the turntable, which we love! Having these parts being rotated while we weld allows us to lay down a beautiful weld without stopping and starting! Another thing we get to use on these parts is ER312 filler rod, which is our favorite stainless steel rod. We call it Super Missile Rod because it can be used to weld unknown or dissimilar alloys of steel or stainless steel!