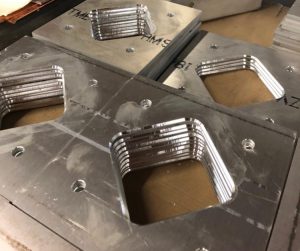

We just completed an order of our popular aluminum cornerblocks. The only reason we don’t get more orders of these than we do is because they are unbreakable! Once you have them, you have them forever. We perfected this design many years ago, and have been doing them the same ever since!

We just completed an order of our popular aluminum cornerblocks. The only reason we don’t get more orders of these than we do is because they are unbreakable! Once you have them, you have them forever. We perfected this design many years ago, and have been doing them the same ever since!

In looking over photos, I realized that we did not post about the enormous aluminum door we made for KD Clark Construction a few months ago (well, enormous to us!).

It’s almost 10 feet by 14 feet by 4 inches deep. Once it’s complete, it will have a glass insert and wood panels on both sides.

One of KD Clark Contruction’s employees sent us a picture of the door as they were testing before sending it out for final paint and finishing

.Can’t wait to see the house when complete!

Peggy Terzian